NovoTrack Completes High-Quality Renovation of NWPU Friendship Campus Track

- Share

- publisher

- Donna

- Issue Time

- Apr 24,2024

Summary

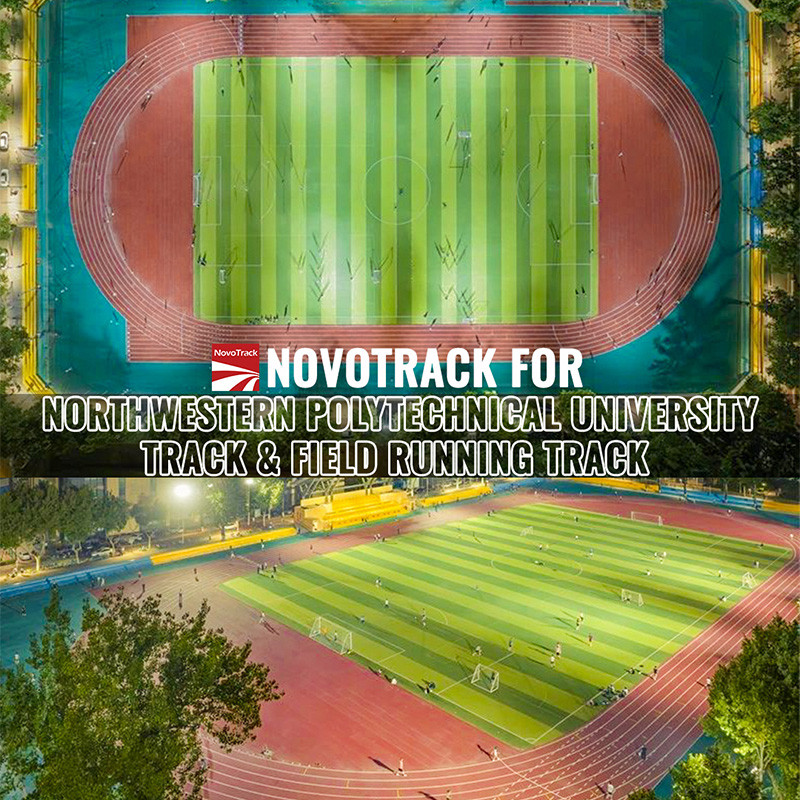

NovoTrack successfully completed the renovation of the track and field runway at Northwestern Polytechnical University's Friendship Campus. The campus infrastructure department ensured quality through rigorous management and precise measurements. The track surface met national standards, and the project was delivered 32 days ahead of schedule. NovoTrack's expertise in rubberized track surfaces was instrumental in the project's success.

With a focus on achieving high-quality results, the campus infrastructure department rigorously managed the construction process of the rubberized track oval at the Northwestern Polytechnical University Friendship Campus. Various measures, including on-site supervision, field experiments, and continuous inspections, were implemented to strengthen process management.

During construction, precise measurements were taken throughout the site using rulers and leveling instruments, ensuring that the surface was uniformly smooth before proceeding with the next area of installation. The tolerance for surface smoothness was set at an error margin of no more than 3mm, with longitudinal slopes not exceeding 0.1% in the running direction and lateral slopes not surpassing 1% from outer to inner edges perpendicular to the running direction. The color consistency of the campus track surface was also maintained, free from any variations.

Furthermore, the physical and mechanical properties as well as the absence of harmful substances in the rubberized running track surface system were verified through testing at the China Athletic Synthetic Track Laboratory, meeting national standards for sports field usage requirements.

To ensure construction quality and minimize project duration, the infrastructure department collaborated with the construction firm to schedule tasks based on weather and temperature conditions, optimizing the construction timeline accordingly.

Initially, updates to the field lighting system were prioritized, followed by enclosed fencing construction. During the winter break, activities such as removing the original surface layer, milling the asphalt base layer, and filling the sandpit foundation were completed. As temperatures rose in spring, the prefabricated rubber running track surface was laid.

Despite challenges such as inclement weather and Level II emergency responses due to heavy pollution, causing a total of 33 days of work stoppage, the project was completed within an effective timeframe of only 70 days. This encompassed the installation of the entire 12,638.84 square meter rubberized track oval, delivering the project 32 days ahead of the contract deadline.

Throughout the process, NovoTrack's expertise in rubberized track surfaces, campus track, rubberized running track surface systems, and track and field running track installations ensured the successful completion of the project.