Football Turf | S-Shape Infilled Sports Turf

- Model

- Football Turf | S-Shape Infilled Sports Turf

Item specifics

- Model

- S-SHAPE INFILLED SPORTS TURF

- Pile Height

- 50 mm

- Density

- 10,500 stitches/m²

- Dtex

- 8,800

- Backing

- PP + Mesh (double-layer)

- Coating

- SBR Latex (Styrene-Butadiene Rubber)

- Warranty

- 3 Years

Review

Description

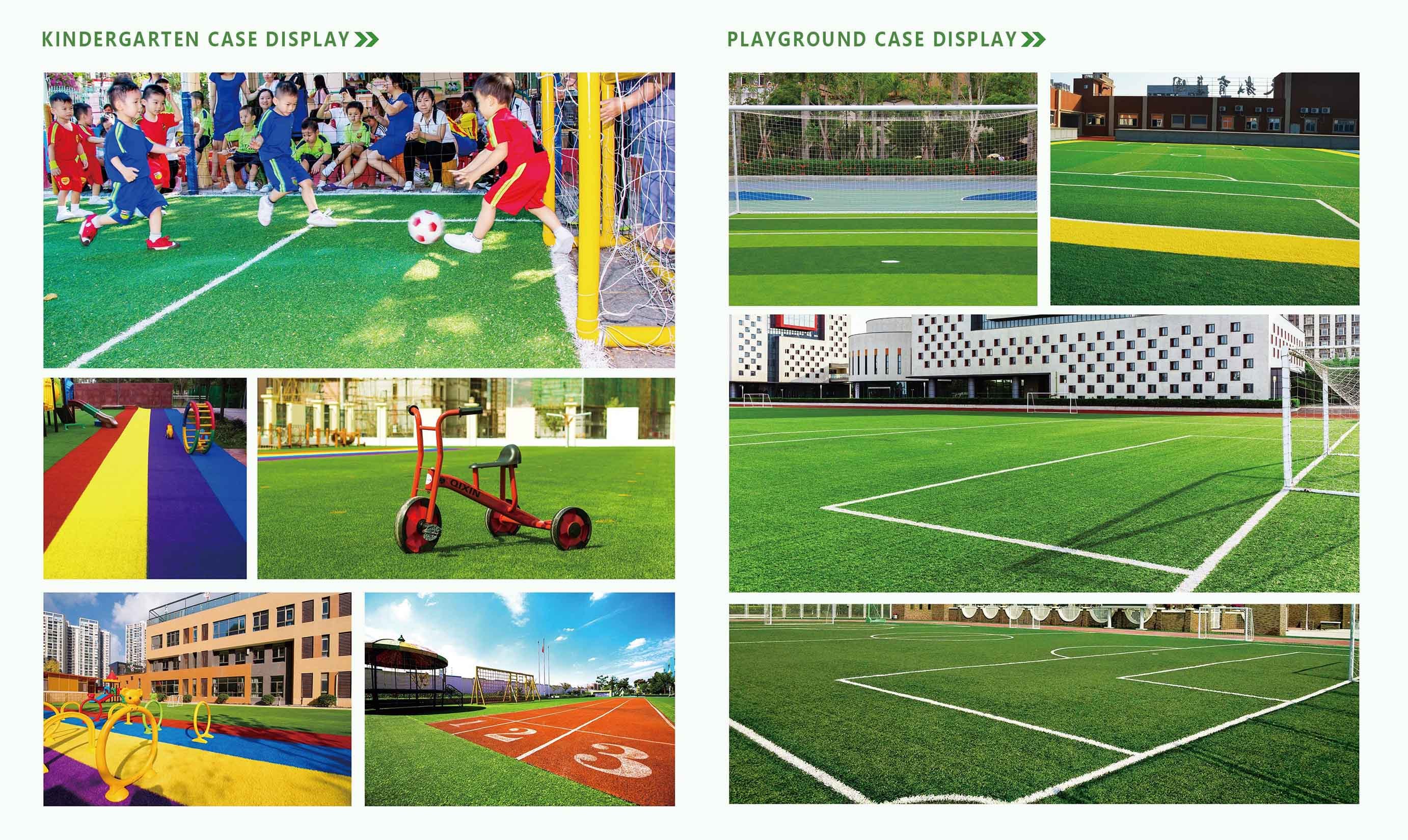

Artificial Turf Application

About NovoTrack Football Turf

NovoTrack Artificial Turf Co., Ltd., established in 2004, specializes in the research, development, manufacturing, and sales of artificial turf. Since its founding, NovoTrack's products have been exported to over 120 countries and regions worldwide. The company offers two main categories of turf: sports turf and leisure turf. Sports turf features high wear resistance, excellent resilience, strong tuft bind, and aging resistance, making it ideal for high-intensity use in football, field hockey, rugby, and other sports fields. Leisure turf emphasizes diverse appearances, vibrant colors, strong weather resistance, UV stability, and environmental friendliness. It is widely used in residential, commercial, and customized spaces, adding greenery and comfort to living and recreational environments.

NovoTrack holds multiple certifications and test reports from internationally recognized sports organizations, demonstrating the company’s leading position in technology and quality.

The company places great importance on R&D and product innovation, continuously leading industry development. As the global sports industry expands and consumer demand for quality of life increases, the artificial turf market continues to grow. Whether in sports facility construction or leisure space design, NovoTrack offers broad development potential and will keep launching innovative products to meet the diverse needs of customers worldwide.

We warmly welcome partners and clients from all sectors to visit us for guidance, cooperation, and business discussions.

About NovoTrack Football Turf Factory

1 Raw Material

The quality of artificial grass begins with the selection of high-quality raw materials. NovoTrack uses internationally recognized high-performance polymers such as polyethylene (PE), polypropylene (PP), and nylon as the base material for grass fibers. These are supplemented with UV inhibitors, antioxidants, and eco-friendly color masterbatches to ensure the grass fibers have excellent weather resistance, anti-aging properties, wear resistance, and color stability. This step is crucial as it forms the foundation for ensuring consistent product performance and longevity, making it essential for high-quality artificial grass for football ground applications.

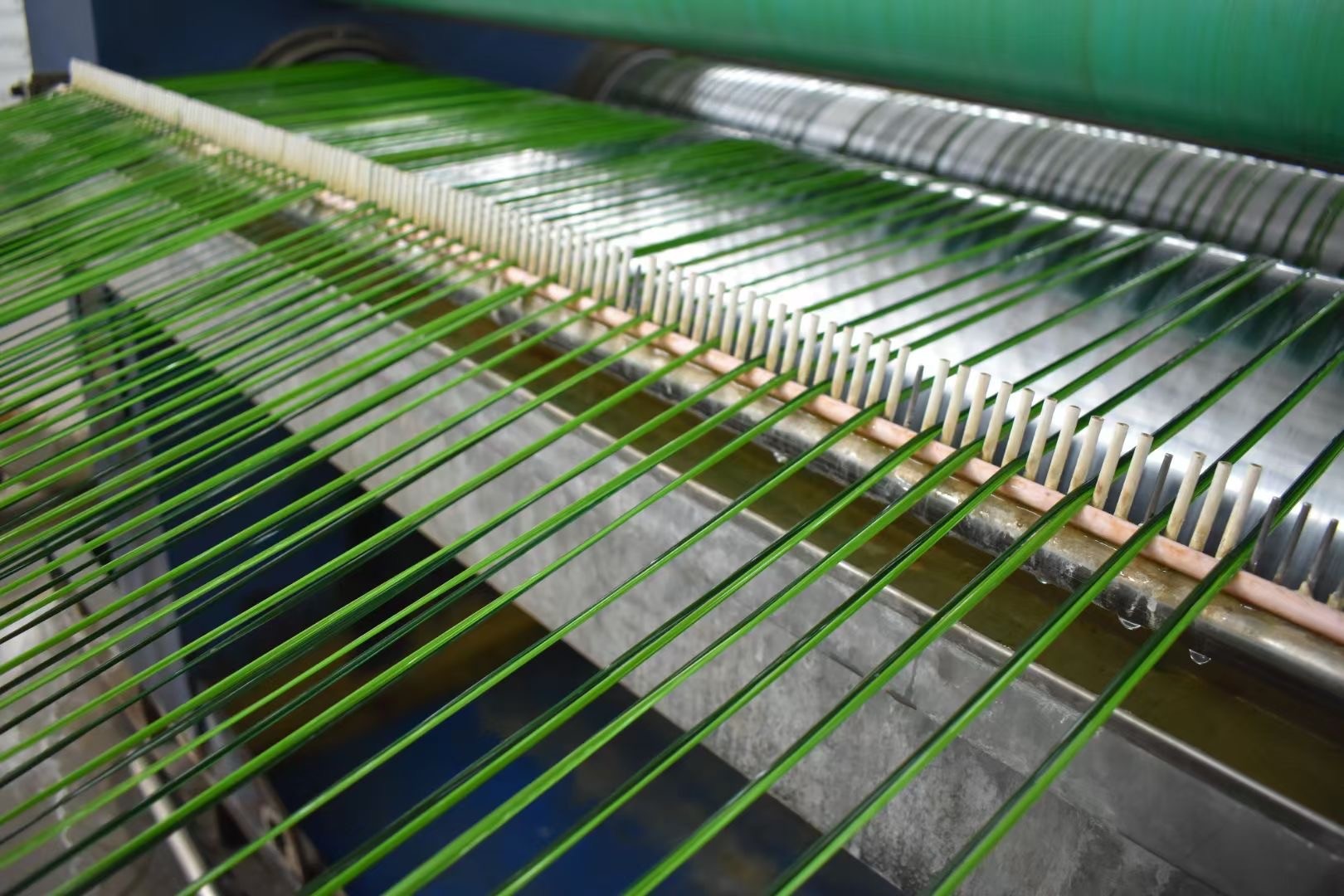

2 Extruding

In the extrusion stage, the carefully mixed raw materials are fed into advanced extrusion equipment, where they are heated and melted to form various shapes of grass fibers, such as S-shaped, U-shaped, diamond-shaped, and oval. The extrusion process determines the cross-sectional structure and physical properties of the fibers, directly impacting their uprightness, flexibility, and athletic performance. The extruded fibers are then cooled, washed, and dried to ensure dimensional stability and a smooth surface, making them suitable for artificial turf football fields and football turf ground.

3 Twisting

Some artificial grass products, particularly those for recreational use, undergo a twisting process after extrusion. In this stage, single or multiple strands of grass fibers are mechanically intertwined or twisted to create a curled effect. The twisting process not only enhances the natural appearance of the grass fibers but also improves their overall fluffiness and anti-collapse properties, making the grass more comfortable and aesthetically pleasing. This step is especially important for synthetic grass turf used in artificial football turf.

4 Tufting

In this step, the grass fibers are evenly implanted into a backing fabric (usually polypropylene-based). Using high-speed tufting machines, the fibers are arranged according to preset row spacing, stitch density, and height to create a dense, even grass structure. This process is key in determining the density, visual neatness, and the comfort and durability of the final product, which is essential for artificial football turf and artificial grass football field applications.

4 Back Coating

After tufting, the grass fibers are securely fixed to the backing fabric using a back coating process. NovoTrack uses environmentally friendly SBR or PU back coating, depending on customer requirements. The back coating not only strengthens the adhesion of the fibers but also improves the product's water resistance, heat resistance, and dimensional stability. After applying the back coating, the turf undergoes a high-temperature curing process to ensure a solid structure that prevents fiber shedding. This is vital for artificial grass football field durability and performance.

5 Packing & Warehousing

After passing inspection, the finished product is packaged into rolls according to different specifications, with a protective PE film to prevent dust, moisture, and UV damage. Each roll of turf is labeled for easy traceability and identification. After packaging, the artificial grass for football ground products are stored in a temperature-controlled, dry warehouse to maintain product quality, ensuring stable conditions before shipment and installation. This guarantees timely delivery to global clients, with the assurance of high-quality artificial football turf at competitive football grass prices.