All Weather Athletic Surface | World Athletics IAAF Athletics track surfacing requirements of pre-fabricatcd system

- Share

- publisher

- Ruth

- Issue Time

- Dec 28,2021

Summary

The requirements of World Athletics IAAF Athletics track surfacing All Weather Athletic Surface pre-fabricatcd systempre-fabricatcd system

All Weather Athletic Surface-pre-fabricatcd system

The athletic track surface is an impermeable synthetic system designed for both National competitions and raining activities in compliance.It is continuous, seamless piece of material.Its good resistance are suitable for athletic competition and training.It is not too abrasive or too hard as to cause skin or other injuries to athletics in events of all.It is not harden,decompose or become tacky.The athletic track system is able to withstand wear and abrasion caused by all track and field events.Ofcourse,it has good color fastness and good ultraviolet light stability.

The surface of synthetic track must be effective.Here are some requirements.

1.No surface imperfections such as bubbles,fissures,delimitation, moisture entrapment, water patches, uncured areas etc.shall be acceptable.The above mentioned imperfections including temporary moisture entrapment shall be considered as defects in the track laying and such defects shall be rectified to the satisfaction of the Engineer. If such defects are present in several numbers in an area of the track, the relevant area shall be re-surfaced to the satisfaction of the Engineer. Until such rectification is done, Works shall not be considered as Completed.

2.The track surface shall be installed so that on a localized level, there shall be no high spots or depressions beneath a 4m straightedge exceeding 6mm. Depressions beneath a 1m straightedge shall not exceed 3mm. There shall be no step-like irregularities greater than 1mm in height Particular attention is to be paid to seams and joints in the surface. The intent is to ensure the safety of athlete and provide even running surface.

3.The Final Track Product shall have minimum of 13mm thickness. There shall be specifically designed areas such as in the javelin runway or other high stress areas where the safety of the athlete and the durability of the surface will dictate that the thickness is greater than the minimum. This additional thickness shall not affect the flatness of the surface.

The thickness of the running surface shall be determined to meet shock absorption,vertical deformation,friction and tensile properties requirements.The ability of the surface to reduce force (absorb energy) is important. The Shock Absorption shall be between 35% and 50%, at any surface temperature between 10 C and 40 C.The ability of the surface to deform under load is important. Too high a deformation can affect the safety of the athlete through instability of the foot, while the inability of the surface to deform can cause injuries due to impact forces. The vertical deformation shall be between 0.6mm and 2.5mm, at any surface temperature between 10 C and 40 C.The safely of the athlete can be adversely affected by slippage between the foot and the surface in a wet or dry condition. Generally friction is achieved through the application of texture to the surface; however the type of footwear will be a iactor. In order to identify the influence of the surface, a standard foot is utilized in the methods employed here for measuring friction. The coefficient of dynamic friction shall be nut less than 0.5 under wet conditions. Since the coefficient of dynamic friction under dry conditions is expected to be higher, only the performance under wet conditions is required.The tensile strength and elongation at break of a surface material will provide an indication of the durability of the surface. When determined using following method, the minimum values stipulated by World Athletics are 0.40MPa for tensile strength and 40% for elongation at break. The test shall be conducted on a minimum of four samples and the result quoted is the average of the four results.

4.The entire synthetic shall be free of TDI,Chlorinated Hydrocarbon and other heavy metals.And it shall be resistant to all weather,ultra-violet light,non-toxic and no volatile organic compounds.

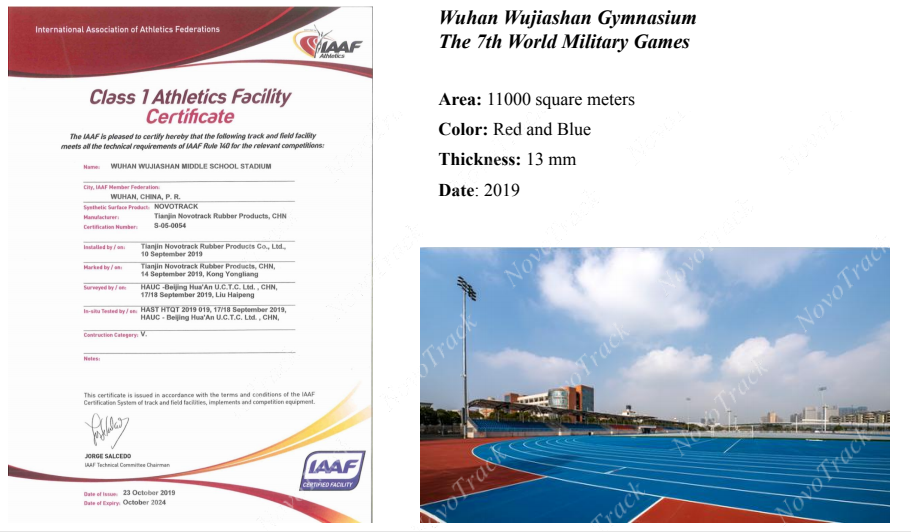

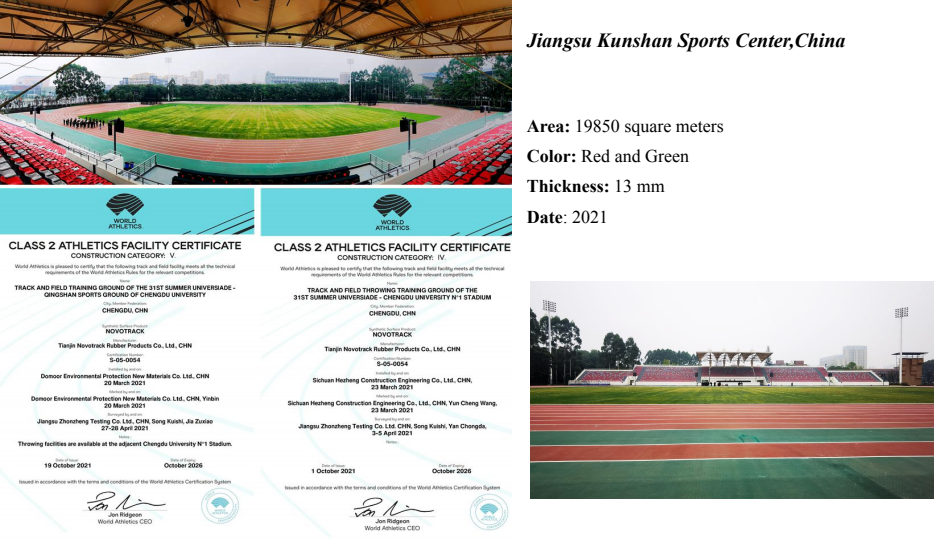

The following are some projects which passed by the World Athletics. Class I and Class II .