Fast Installation: NovoTrack Prefabricated Rubber Running Tracks Save Construction Time

- Share

- publisher

- Donna

- Issue Time

- Jul 8,2024

Summary

In the modern sports facility construction landscape, time and efficiency are critical factors. Schools and community sports facilities demand rapid installation with minimal disruption to regular activities. NovoTrack's prefabricated rubber tracks offer the perfect solution, significantly reducing construction time while ensuring high-quality athletic surfaces.

In the modern sports facility construction landscape, time and efficiency are critical factors. Schools and community sports facilities demand rapid installation with minimal disruption to regular activities. NovoTrack's prefabricated rubber tracks offer the perfect solution, significantly reducing construction time while ensuring high-quality athletic surfaces.

Advantages of Prefabricated Rubber Tracks

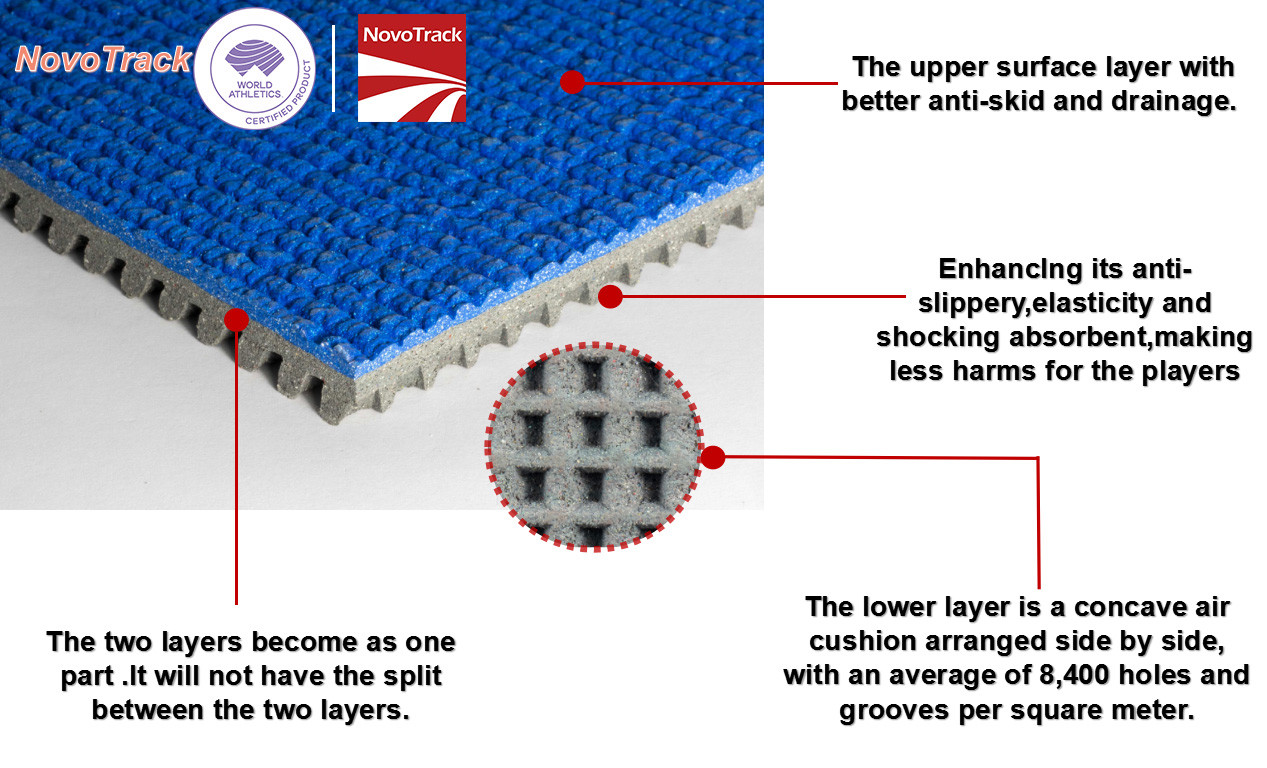

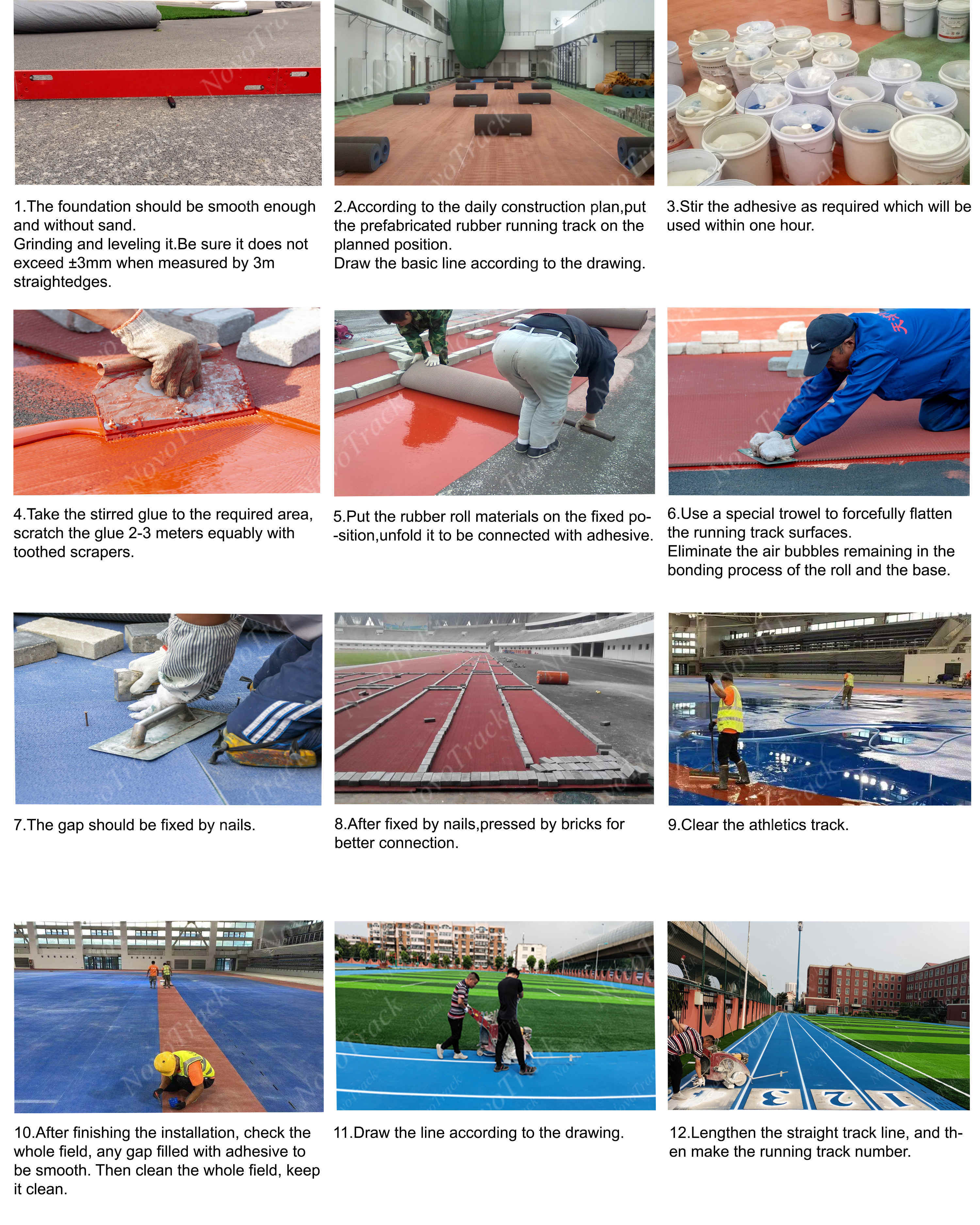

NovoTrack prefabricated rubber tracks are made from high-quality recycled rubber materials, pre-manufactured in a controlled factory environment. Unlike traditional poured-in-place tracks, these prefabricated tracks do not require on-site mixing and installation, greatly reducing the overall construction time. Each prefabricated track section is precisely measured and quality-controlled, ensuring seamless integration and optimal performance upon installation.

Simplified Installation Process

The modular design of NovoTrack prefabricated rubber tracks simplifies the installation process significantly. Construction crews only need to transport the prefabricated track sections to the site and assemble them according to the design plan. The standardized modules minimize complex operations on-site, significantly lowering both the difficulty and time required for installation.

Environmentally Friendly and Low Disruption

Another key advantage of rapid installation is the reduced environmental impact and minimal disruption to surrounding activities. Traditional track installations often take longer and may generate noise and dust, affecting the nearby environment and people. NovoTrack's quick installation process mitigates these adverse effects, allowing schools and communities to resume normal activities in a shorter timeframe.

Efficient Project Examples

NovoTrack prefabricated rubber tracks have demonstrated their efficiency in numerous projects. For example, a high school track renovation project initially scheduled to take a month was completed in just two weeks using NovoTrack's prefabricated rubber tracks. The quick installation not only met the timeline but also received high praise from the school administration and students for the track's quality.

Maintenance and Longevity

Fast installation does not compromise quality. NovoTrack prefabricated rubber tracks are designed and manufactured to high standards, ensuring durability and safety in actual use. The track surface has excellent UV resistance and wear resistance, maintaining its performance over time and reducing the frequency and cost of maintenance.

Conclusion

NovoTrack prefabricated rubber tracks, with their fast installation, minimal environmental impact, high quality, and long lifespan, are the ideal choice for school and community sports facility construction. In a modern construction environment that values efficiency and quality, NovoTrack prefabricated rubber tracks offer a time-saving and effective solution that meets the demand for high-quality athletic surfaces. As technology continues to advance and wider adoption ensues, NovoTrack will lead the way in the innovation of prefabricated rubber tracks, providing convenience and exceptional sports experiences for more users.