Comprehensive Guide to Running Track Installation by NovoTrack

- Share

- publisher

- Donna

- Issue Time

- Aug 30,2024

Summary

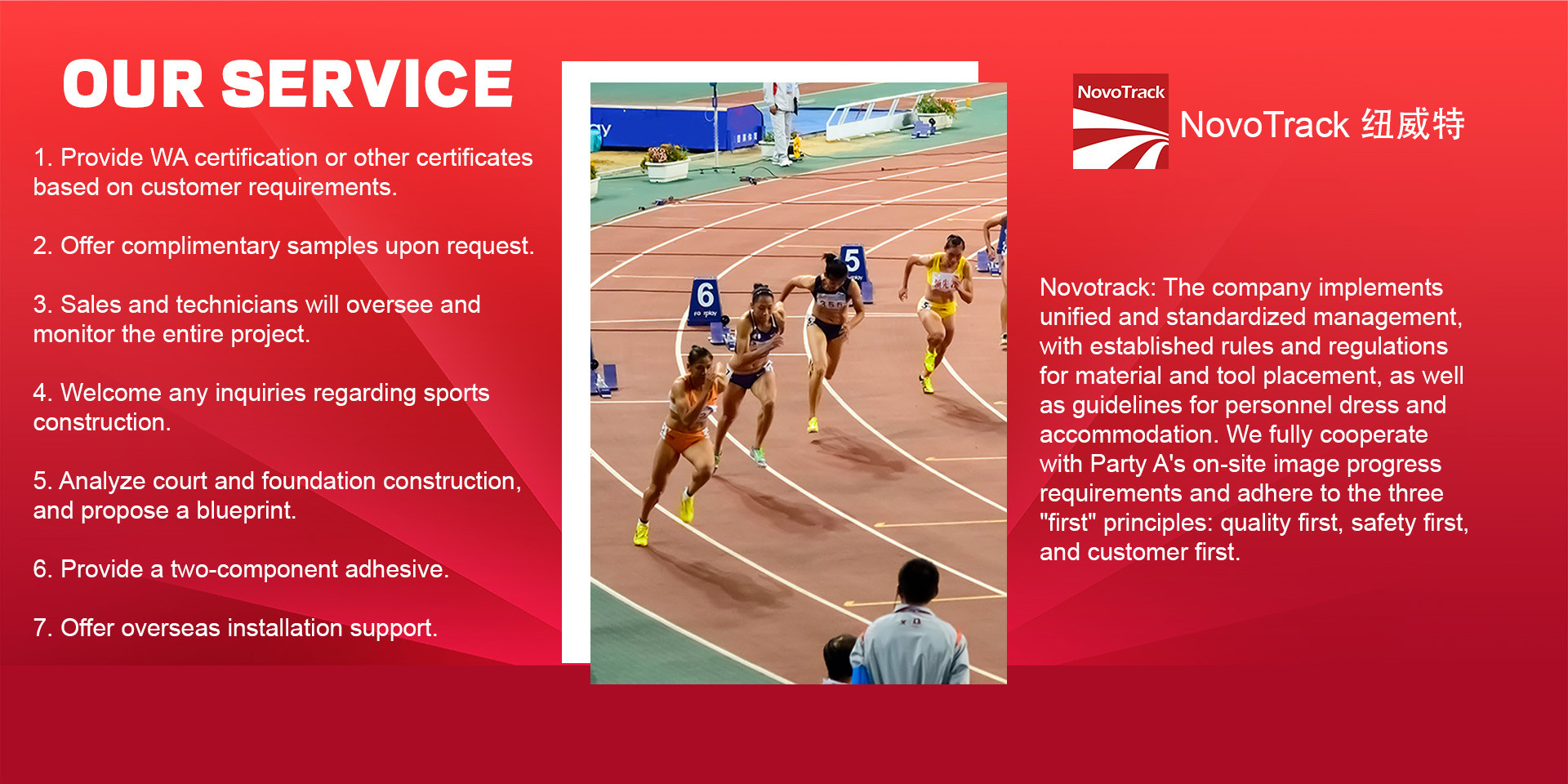

NovoTrack has the expertise and knowledge to create quality running tracks for any venue. Our team will evaluate your needs and provide suggestions for top performance. With experience in constructing and repairing over 100 running tracks for sports fields, K-12 schools, kindergartens, and park trails, NovoTrack provides a turnkey solution to get your team running in no time.

Introduction

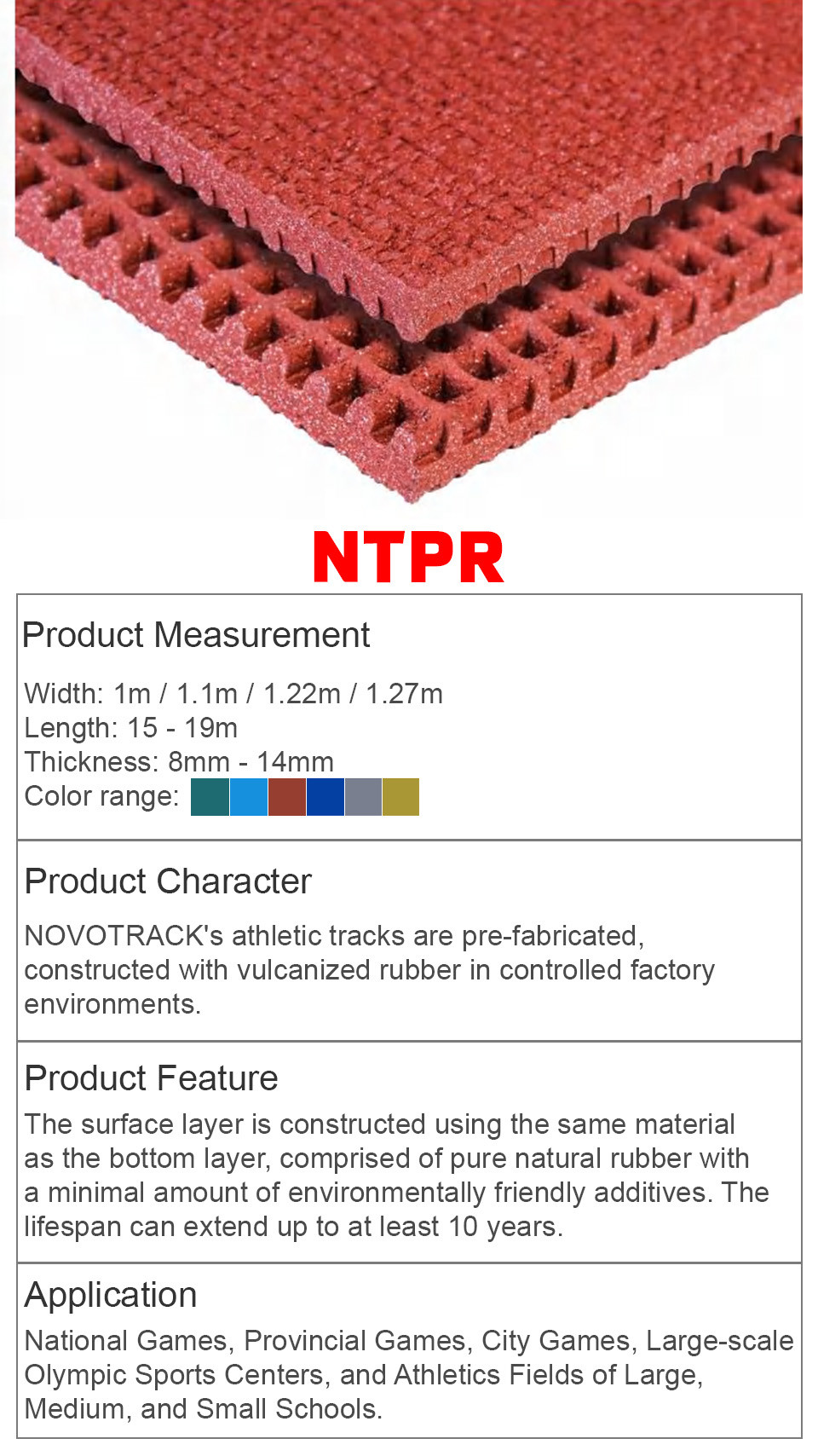

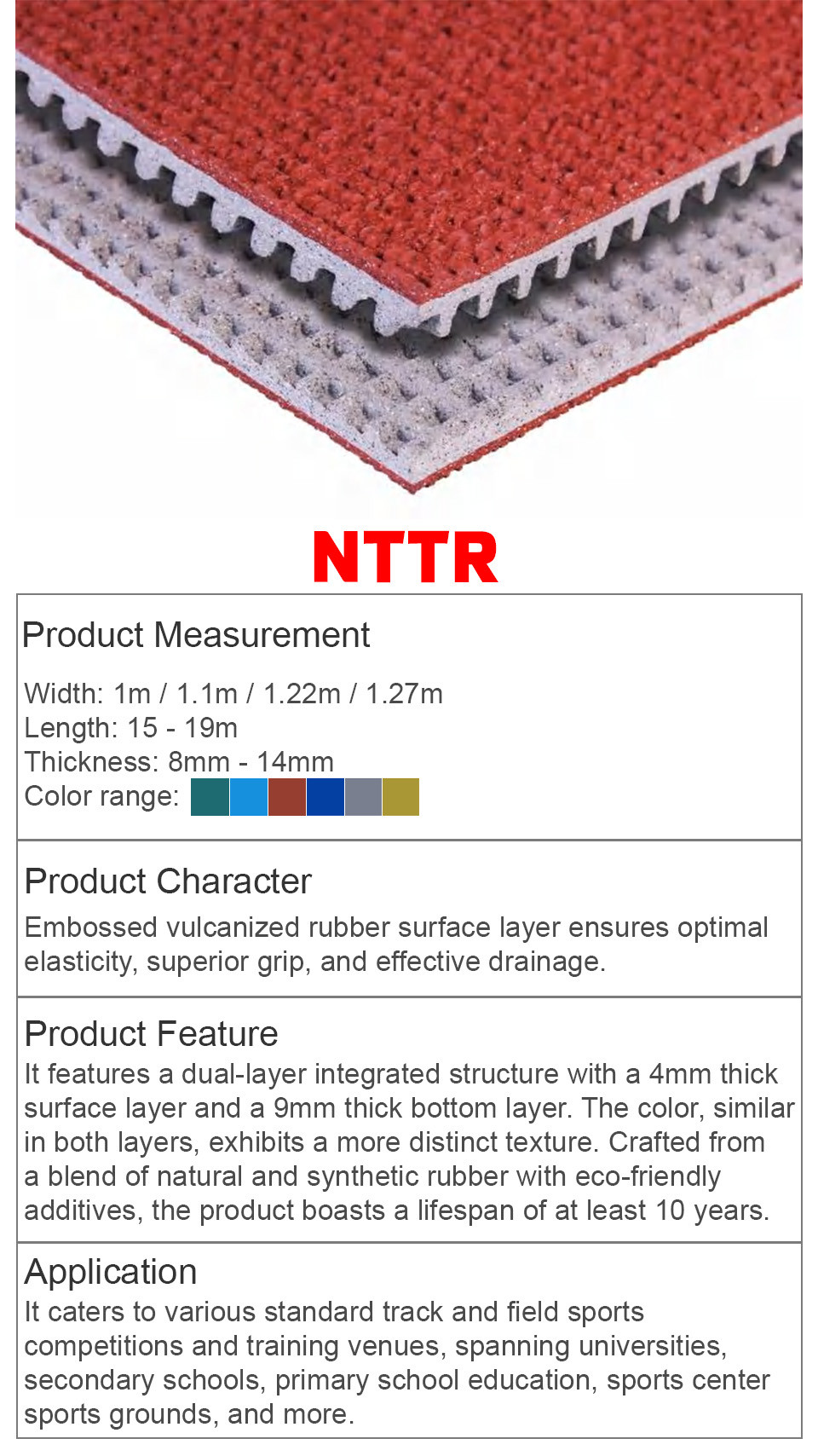

NovoTrack has the expertise and knowledge to create quality running tracks for any venue. Our team will evaluate your needs and provide suggestions for top performance. With experience in constructing and repairing over 100 running tracks for sports fields, K-12 schools, kindergartens, and park trails, NovoTrack provides a turnkey solution to get your team running in no time. Here are two of our best-selling running track products. Click on the images to view product details.

Step 1: Planning and Design

Running track installation begins with thorough planning and design. NovoTrack's experts conduct a site evaluation to measure the area, analyze the terrain, and assess drainage conditions. We then create a customized design that meets the specific needs of the venue, ensuring optimal performance and compliance with industry standards.

Step 2: Site Preparation

The next step in the installation process is site preparation. This involves clearing the site of debris, vegetation, and any other obstacles. A proper drainage system is also installed or upgraded to ensure the longevity of the track.

Step 3: Base Construction

A strong base is crucial for the durability of a running track. NovoTrack ensures the base is properly graded and compacted to provide a stable foundation. A layer of crushed stone or aggregate is then laid down, offering the necessary support for the subsequent layers.

Step 4: Track Surface Installation

The surface installation is a critical phase in running track installation. The process begins with laying an asphalt or concrete layer to create a smooth, even base. NovoTrack then applies multiple layers of synthetic material, such as polyurethane or rubber, which are evenly spread and compacted to create a resilient and durable track surface.

Step 5: Line Marking and Finishing

Once the surface is installed, precise line marking is applied according to international or national standards. This step ensures that the track is ready for competitive use. NovoTrack also applies a finishing treatment to enhance the track's slip resistance and overall durability.

Step 6: Quality Inspection and Handover

Before the track is handed over, a thorough quality inspection is conducted to ensure every aspect meets NovoTrack's high standards. Once approved, the track is ready for immediate use.

Q&A: Common Questions About Running Track Dimensions

Q: What are the dimensions of a 400m running track?

A: A standard 400m running track typically features two straight sections and two curves, forming an oval shape. The length of each straight section is usually 84.39 meters, and each curve has a radius of about 36.5 meters. The total length around the innermost lane is 400 meters.

Q: What are the dimensions of a 200m running track?

A: A 200m running track is generally used indoors and is half the size of a standard 400m track. The straights are approximately 35-40 meters long, with curves that have a radius of about 17-18 meters. The total length around the innermost lane is 200 meters.

By choosing NovoTrack, one of the leading running track installation companies, you are assured of a running track installation process that is efficient, precise, and tailored to your specific needs. For more information on track dimensions or any other queries, feel free to contact us!